Ultrasonic

DIVING DEEP: ADVANCING UNDERWATER TECHNOLOGY AND COMMUNICATION

The Sonar Research Group conducts research and development of next-generation technologies for the naval and commercial underwater domains. This includes designing and prototyping ultrasonic transducers and arrays, and undertaking a range of acoustic, electrical and pressure-related tests. Current projects include high-resolution underwater imaging using synthetic aperture sonar arrays, as well as the development of broadband underwater communication technology for real-time data exchange between autonomous underwater vehicles and surface vessels.

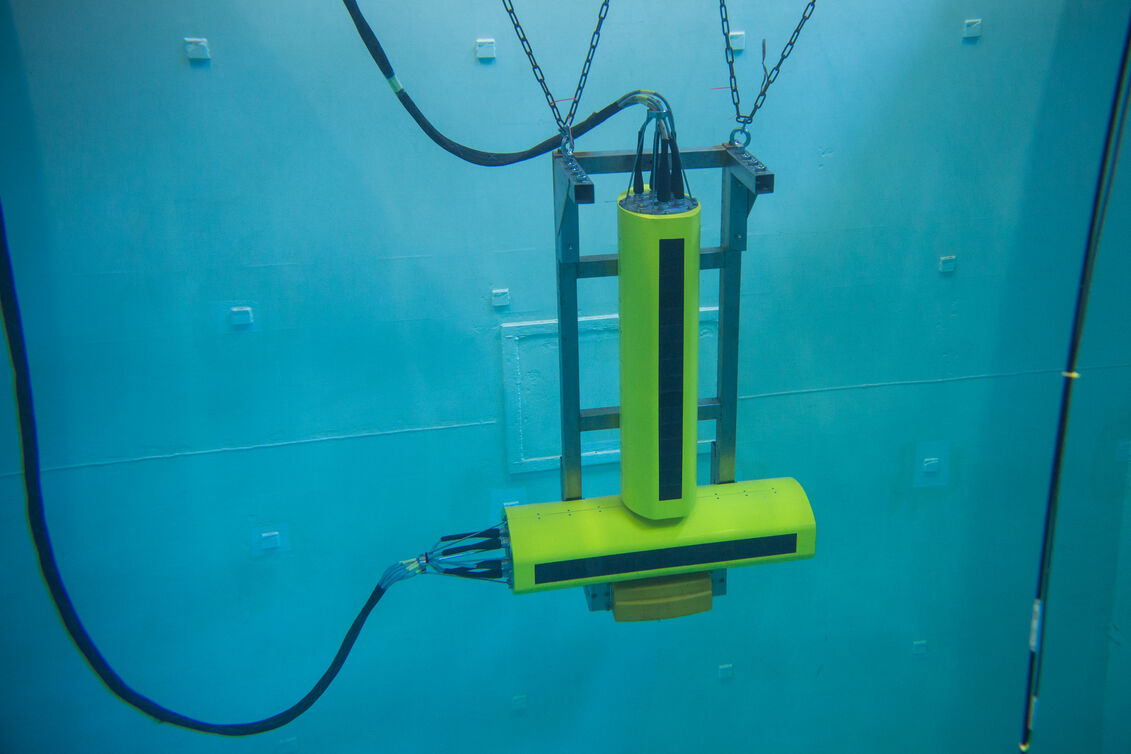

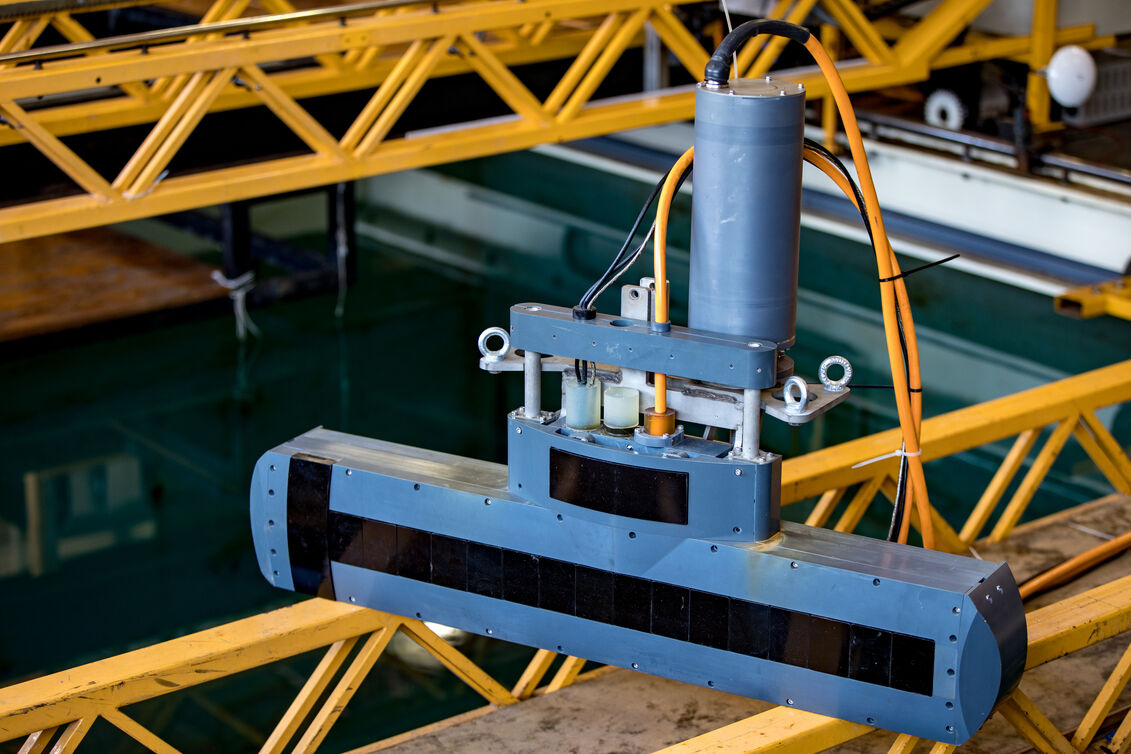

Sonar wet-end transducers and arrays

In collaboration with the South African Navy and Armscor, the CSIR has developed a range of wet-end sonar transducers and arrays for specialised underwater applications. This includes all stages, from research on piezoelectric composite materials and broadband ultrasonic transducers, developing customised acoustic modules from the kHz to 100 kHz range and building transmit/receive electronics and computer-based user interfaces and signal-processing software. Projects are undertaken within a quality management system that is compliant with ISO 9001.

To facilitate the transition of research and development outputs to market/field use, the team has established a small-volume manufacturing capability that ensures full configuration management is performed and manufacturing procedures can be tested and finalised prior to technology transfer. This capability is also used to support the fleet operations of the South African Navy by manufacturing the wet-end sonars under the license of foreign original equipment manufacturers (Thales Underwater Systems and Atlas Elektronik).

Recent research projects have seen the development of technology for high-resolution 3D imaging (at a mm-scale), high bandwidth/data-rate underwater data communications and synthetic array sonar for eventual application on an underwater vehicle.

Real-time detection of breaks on heavy-freight railway lines

In collaboration with Transnet Freight Rail and Armscor’s Institute for Maritime Technology, a world-first ultrasonic inspection system was developed to monitor heavy freight railway lines for breakages in remote areas.

The Ultrasonic Broken Rail Detection (UBRD) system detects breaks using ultrasound waves that are guided within the railway lines over distances of around 1 to 2 km and wirelessly communicates alerts to a control centre.

The CSIR’s skills are in the modelling of the guided waves as well as the development of ultrasonic transducers to excite them and the signal processing algorithms to process the signals.

Current research aims to advance the technology, with the goal of detecting and classifying rail defects prior to them developing into complete breaks. Achieving this would be a paradigm shift from rail-break detection to prevention.

The UBRD system has been rolled out on the entire 860 km long Sishen-Saldanha iron ore freight line in South Africa and is actively preventing derailments 24/7.

The Broadband Acoustic Underwater Data Communication System

The Broadband Acoustic Underwater Data Communication System (BUDC) is an advanced technology that enables high-speed wireless data communication underwater. This innovative system utilises wideband transducers and acoustic waves to transmit and receive large amounts of data at high data rates, overcoming the limitations of traditional communication methods in underwater environments. The BUDC system is designed to address the challenges of underwater communication and is suitable for various applications, such as AUV communications, oceanographic research, offshore oil and gas exploration, and underwater surveillance.

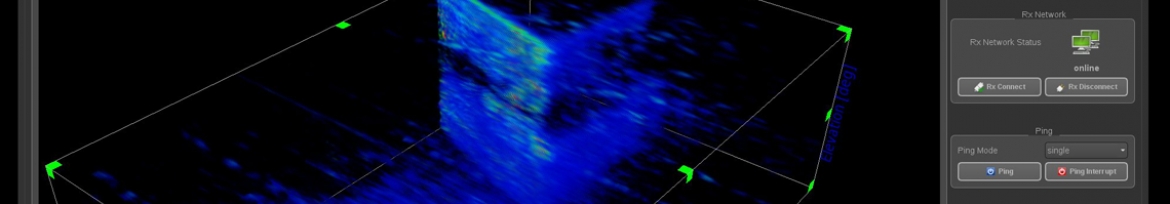

Synthetic Aperture Sonar (SAS)

Synthetic aperture sonar (SAS) is an acoustic imaging technique used to obtain high-resolution images of the acoustic reflectivity profile of the seafloor. This is achieved by synthesising a very long aperture through the transmission of a known signal and the reception of echoes from the bottom of the seafloor along a rectilinear path. The Echoes are then stored in memory and processed coherently to form a high-resolution image of the seafloor.

The resolution of SAS images can be shown to be equal to half the size of the sensor used in the acquisition process described above, and it is independent of the frequency, and range of imaging. This is significant because other types of sonar imaging produce resolutions that vary with frequency and range. As an analogy, images from SAS are akin to those seen on an HD TV, while other sonar imaging techniques produce images akin to standard definition resolution. Synthetic aperture sonar, therefore, becomes the preferred imaging method for a wide range of applications requiring high-resolution long-range imaging such as high-resolution seafloor mapping, mine countermeasures, small object search and rescue, pipeline inspection, marine archaeology, and geological surveying, to mention a few.